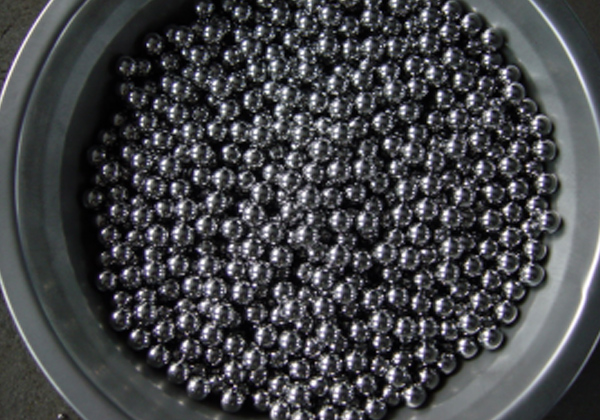

Grinding balls / Polishing balls

Grinding balls can be manufactured from various materials, including steel, aluminum, ceramic, glass, etc. A wide variety of manufacturing materials can meet different tasks and needs. For example, ceramic grinding balls are often used in food processing, while steel balls are often used in heavy industrial situations.

Grinding balls are often mass-produced and sold in kilograms. There is no precise requirement for their accuracy. Still, they must be reliable and wear-resistant to suit different industrial needs, such as hardness, surface, cleanliness, etc. Grinding balls can be customized for any task that requires grinding.

| Specification | |

|---|---|

| Material | AISI1010/1015/1085/52100; AISI302/304/316/316L/420/440C |

| Diameter | 0.5mm – 50.8mm |

| Precision Grade | G200, G500,G1000,G2000 |

| Technical Data | ||||

|---|---|---|---|---|

| Steel Material | Density

[g/cm3] |

Hardness

[HRC] |

Ultimate compressive strength

[MPa] |

Service temperatures

(min/max) [°C] |

| AISI 52100 | 7.80 | 60 – 66 | 2500 – 2600 | -60 / 150 |

| AISI 1010/1015 | 7.82 | 55 – 65 | 1500 – 2000 | -40 / 500 |

| AISI 1085 | 7.85 | 59 – 66 | 2000 – 2500 | -40 / 500 |

| AISI 302/ 304/304L | 7.95 | 20 – 39 | 150 – 300 | -196 / 700 |

| AISI 316/316L | 7.95 | 20 – 39 | 150 – 300 | -196 / 600 |

| AISI 420 | 7.74 | 48 – 60 | 1100 – 1400 | 0 / 400 |

| AISI 440C | 7.70 | 57 – 65 | 1200 – 1500 | 0 / 400 |

| AISI 52100 | 7.80 | 60 – 66 | 2500 – 2600 | -60 / 150 |

| AISI 1010/1015 | 7.82 | 55 – 65 | 1500 – 2000 | -40 / 500 |

Applications: Grinding different mixtures (concrete, food, etc.), ball mills, roll, and vibration finishing, polishing, shot peening, and filtration systems. They are often used as packing or cover elements in electrical, hydraulic, or thermal applications. Examples include processing grain in food production systems, working concrete to the desired consistency, or in shot peening equipment for strengthening automobile crankshafts.

Choosing the right media for grinding and milling operations is crucial. Grinding media are used to grind or crush the material to reduce particle size and refine the material. Grinding media come in a wide variety of materials, shapes, and sizes. Which media is appropriate depends on the context of the intended application. The properties affect how the material is processed and the duration of the medium.

SDBALLS Industries is a professional ball manufacturer with an annual production of more than 5000 tons of grinding balls. The surface of our grinding media is smooth and flawless, the hardness is up to standard, and the packaging is clean and neat, which has been highly recognized by customers in various industries. We have been supplying our customers all over the world with our quality made-in-China products, with the best price and standards to provide the highest quality products. If you are unsure of what media you need, we offer a free consultation to ensure you get the best product for your operation.

Schedule A Request

Get in touch with us today for any service. (*) Indicates required fields.